The practice of the 1280mm blast furnace of Sinosteel No. 1 on rest, stop and start

Abstract: The material surface is lowered to the tuyere belt through the top of the furnace, and the damaged cooling wall water pipe is treated, and the damaged furnace wall is sprayed and lined to achieve a reasonable furnace shape. After the furnace is opened, (Al2O3) in the slag is below 15%, and (MgO) is around 8.5%, which has played a positive and effective role in the rapid production of the furnace. This paper focuses on summarizing the successful experience and operation deficiencies of blast furnaces in the process of spraying, lining, stopping and starting the furnace.

Key words: blast furnace shutdown, gunning and drying furnace open

1 Introduction

Sinosteel's 1#-1280m3 blast furnace is designed with 20 tuyere ports and two iron ports, arranged at 180°. The furnace top adopts WP bellless furnace top, and the furnace bottom and hearth adopt "carbon brick + ceramic cup" and water-cooled furnace bottom structure. The blast furnace was put into operation on September 26, 2010, and was shut down for repairs on November 17, 2015. The total molten iron production was 5837351.14t, and the iron output per unit furnace capacity was 4560.43t. During the service period of nearly 5 years and two months, the overall furnace condition was stable and forward, and there was no excessive furnace condition abnormality. However, as the furnace operation entered the middle and late stage, the water pipes of the cooling stave of the blast furnace body were seriously damaged. Before the shutdown, a total of 83 water pipes were damaged, mainly concentrated in sections 7 to 9 (42) and section 12 (22). This not only restricts the improvement and optimization of blast furnace economic and technical indicators, but also threatens the safety, stability and longevity of blast furnace production. Therefore, after the company's research and decision, the 1# blast furnace will be shut down for repairs, and the water system of the main body will be reconstructed.

2 Empty material line shutdown operation

2.1 Preparation before shutdown

Keeping the blast furnace forward before shutdown is the basis for safe shutdown. To this end, the blast furnace operation consciously adopted a charging system to activate the furnace wall and properly develop the edge three days in advance. A certain proportion of manganese ore is added to wash the furnace to maintain sufficient hearth temperature and suitable slag basicity in the process to achieve the purpose of active hearth.

(1) At 14:06 on November 14th, the charge structure was adjusted from A80%+Q20% to A79%+Q21%, the binary basicity of the slag was reduced by 0.03, and 500kg/batch of manganese ore was added to improve the fluidity of slag and iron and ensure that the Hearth active.

(2) When adding manganese ore to wash the furnace, the charging system is changed from C37235232.5230.32232↓O37335332.5330.32↓ to C37235232.5230.32232↓O37235332.5330.32↓, and the material line is 1.3m, so as to properly develop the air flow at the edge to flush out the adhesion of the furnace wall , to create good conditions for the shutdown of the furnace for gunning and lining.

(3) At 6:00 on November 17th, all coke smelting was changed, manganese ore was 300kg/batch, and the ore batch was reduced from 33t to 26t. The coke load decreased from 3.86 to 2.30 in stages, which ensured that the furnace temperature was sufficient. Before the furnace was stopped, the pig iron [Si] was 1.30% to 1.60%, and the physical heat of the molten iron was abundant.

(4) Four furnace top water pipes are made, which are required to extend into the furnace with an effective length of 3700mm, and the front ends of the water pipes are blocked. The surface is divided into three rows of water-pulling holes with a diameter of Φ4mm to ensure a good atomization effect when water is being drawn.

2.2 Pre-break air, empty material line operation

At 14:30 on November 17th, the material line was consciously emptied, and when the top temperature rose to about 220 °C, the material was pressed to cool down. When the wind breaks, the material line is preempted to about 6.0m, and the surface coke is 48 tons. The pre-break wind will be carried out from 16:24 to 17:27 on November 17, with a total wind break of 183 minutes. The following preparatory work has been done during the pre-break period:

(1) Install the water pumping device on the top of the furnace. Install 4 water pipes with a length of 4.5m, a diameter of Φ42mm and a thickness of δ4mm from the cross temperature measuring hole of the furnace throat. The front end of the water pipe is sealed and connected to the high-pressure water source, and the water pipes in four directions are equipped with control valves and water flow meters.

(2) Connect a φ32mm gas sampling pipe from the rising pipe, and lead it to the tuyere platform with a φ32mm black rubber pipe.

(3) Deal with the gas system, fully open and fix the top of the furnace and let it loose. Close the gravity shut-off valve and seal the sand, and close the bag inlet and outlet air blind valves.

At 19:27 on November 17, the feed line was re-ventilated, and all the gas was released into the atmosphere. Shortly after the start of the empty material line, when the air volume reaches the predetermined air volume of 2300m3/min, the wind pressure is 127kPa and the top temperature is about 200℃. A big knock occurred at 20:03, the top pressure suddenly increased from 14kPa to 65kPa, and the wind was immediately reduced by 100m³/min for control. When the top pressure was continuously decreasing, it was accompanied by a small knock, and then returned to the normal top pressure of 12kPa. The knocking was mainly caused by the excessive control of the initial water intake. After that, there was another big knock at 20:49, the top pressure rose from 12kPa to 28kPa, and the wind was reduced by 100m3/min; at 21:17, the third big knock, the top pressure suddenly increased from 13kPa to 62kPa, and the wind was reduced by 100m³ in time /min control, followed by three consecutive small knocks. In order to reduce or avoid knocking, the top temperature is then controlled between 280°C and 350°C. The position of the material surface is calculated based on the air volume of 150,000m³ falling by 1 meter, and the air volume is controlled according to the planned time node and the measured drop position of the material surface. At 22:45, the wind was reduced by 100m³/min, and at 23:48, the wind was reduced by 100m³/min, and no knocking occurred in the process of lowering the material surface in the later stage. By 5:30 on the 18th, slag hanging and air blowing appeared in the tuyere, and iron was opened once. By 6:30, when all the tuyere blows out and sees black, stop the top of the furnace to draw water, and end the operation of the empty material line.

This time, the 1# blast furnace adopts the method of combining the furnace throat atomizing water device and the cross temperature measuring water pumping device to carry out the empty material line. Although large and small knocks occurred 8 times during the empty material line, no gas explosion, other equipment or personal accidents occurred. The empty material line was relatively smooth, and the expected goal of speed and safety was basically achieved. The empty material line took a total of 11 hours, 2 hours ahead of the planned calculation time, and the cumulative air consumption was 158wm3.

3 Gunning and lining operation

3.1 Preparations before gunning

After the end of the empty material line at 6:30 on November 18, the cold and hot air main pipe continued to be supplied, and the conditions for gunning and feeding into the furnace were completed at 8:30 on the 19th. Remove all the small tuyere covers and straight blowing pipes in front of the furnace, and the middle tuyere covers take the two iron ports as the center line, and remove 10 in total. The residual dead coke column in the furnace core is flattened, and 8m3 of river sand is added to press the fire. The purpose is to isolate the air, prevent the coke from continuing to burn in the furnace, prevent the temperature of the hearth from further reducing, and also facilitate the removal of gunning rebound materials. Because the furnace was cleaned thoroughly before the empty material line was shut down this time, the furnace wall was very clean and there was almost no adhesion. Therefore, only a simple cleaning of the furnace wall was carried out before gunning. At 19:00, the gunning and lining equipment will be installed, and the damaged cooling stave will be confirmed at the same time to facilitate the installation of copper cold rods; repair welding anchor hooks will be carried out in the local area without cooling stave, so that the gunning material can be firmly attached to the furnace wall. combine.

3.2 blast furnace gunning and lining

The gunning started at 16:10 on November 21. This gunning was carried out in three stages from top to bottom. In the first stage, gunning is carried out according to the thickness of 50-80mm to find the contour; in the second stage, the thickness is about 50mm; in the third stage, the gunning is carried out according to about 30mm. Due to the relatively large dust in the gunning process and the relatively fast consolidation of the material, in order to effectively ensure the gunning thickness, we require that a 150mm ruler be inserted into the gap of the cold plate every two sections, and this is used as a measure to verify the gunning thickness. standard. At the same time, the rebound material is cleaned up in time for secondary use in the process. The entire gunning ended at 7:00 on November 23, a total of 39 hours, 223.14 tons of materials were used, and the reverse material rate was 3.59%, which was controlled within 5.0% of the technical requirements.

4 Blast furnace, open furnace

4.1 Oven

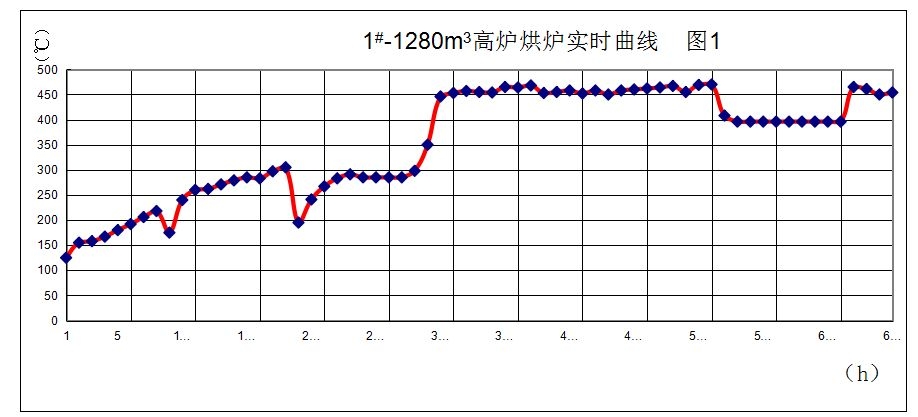

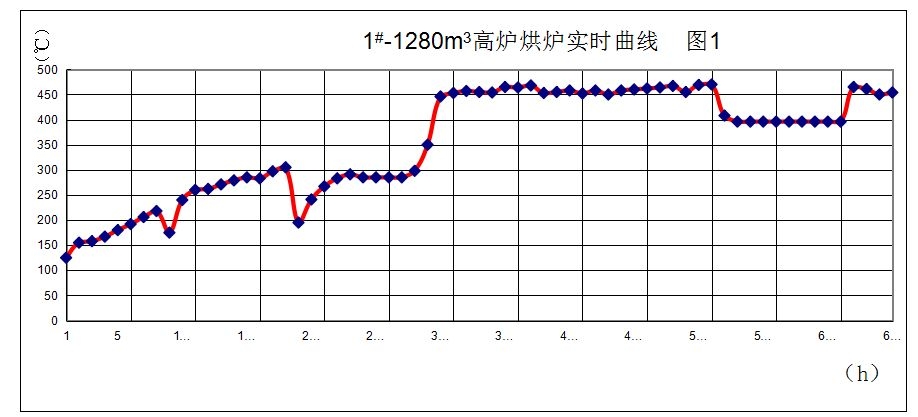

The blast furnace started at 16:30 on November 29 and ended at 8:16 on December 2, with a total time of about 65 hours, 21 hours longer than planned. In addition, during the oven process, pressure leak detection and air stop to deal with the leakage of the hot air main pipe lead to the failure of the oven to continue, resulting in a relatively large fluctuation of the oven curve. During the drying process, due to the limitation of the hot air main pipe and the vertical pipe baking, and the temporary oven thermocouple is not installed in the iron hole, the temperature change of the hearth can only be indirectly reflected by the hot air temperature. Therefore, the air volume of the oven did not reach 1200m³/min as required, which affected the blast furnace oven effect. The actual oven curve is shown in Figure 1 below.

4.2 Determination of furnace smelting parameters

In order to ensure the smooth progress of this furnace opening, the relevant blast furnace technicians determined the whole furnace coke ratio after many discussions: 3.45, normal material coke ratio: 0.80; normal material basicity: 0.95; empty coke basicity: 0.85; slag ( Al2O3)≤15%, (MgO)=8.5~9%; the material line is 1.5m; the normal material compression rate is 11.5%, the air coke compression rate is 13%, and the net coke compression rate is 14%; ore batch 15t; coke batch 7.28t . The ratio of ore into the furnace: sintering 85% + ball 15%; molten iron control requirements: [Si] 3.50%, [Mn] 1.50%, [Fe] 91.5%, [S], 0.060%, molten iron temperature> 1470 ℃.

4.3 Opening the furnace and charging

From bottom to top, the charging materials for this furnace are respectively bottom coke, clean coke, empty coke, normal material + empty coke, and normal material. The original plan was to charge with air, but in fact, considering that the coke in the hearth would catch fire, it was changed to static charging.

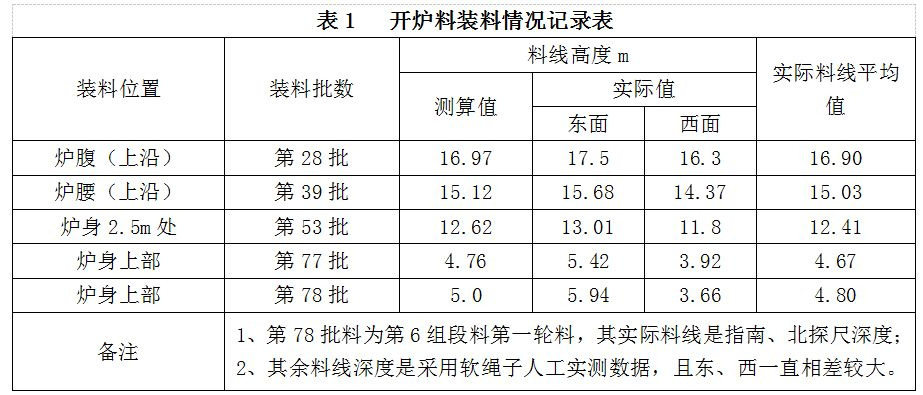

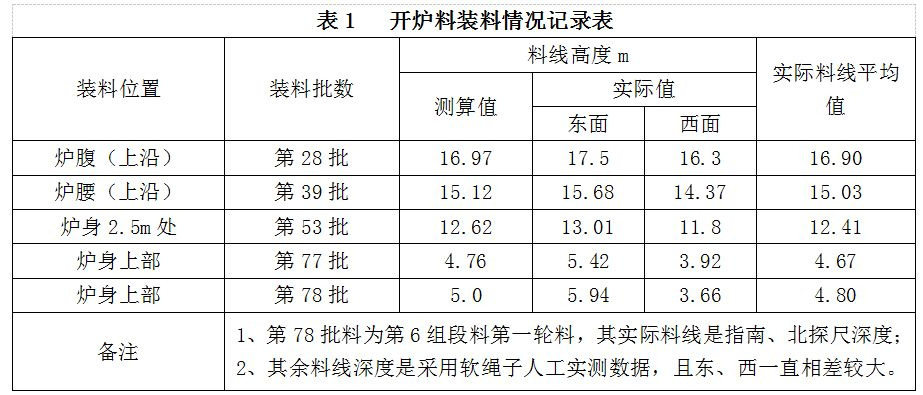

Starting at 10:10 on December 2, 2015, loading 7 batches of bottom coke, 26 batches of clean coke, 20 batches of empty coke, and 26 batches of light material (normal material + empty coke), December 2 21: 10 Charges It took 11 hours to complete the accumulative charge. During the loading process, in order to make the material surface as flat as possible, adjust the cloth angle once every five batches. Due to the accurate selection of parameters for batching calculation in the early stage, and the accurate calculation of furnace capacity after gunning, there is almost no difference between the actual loading height of each section of material group and the theoretical calculation. For details, see Table 1 of the charging record.

4.4 Ignition of blast furnace supply air

At 22:30 on December 2nd, air supply and ignition, open the furnace and block 4#, 5#, 6#, 7#, 14#, 15#, 16#, 17# tuyere, and use 12 tuyere to supply air. The initial air volume is 800m³/min, the hot air pressure is 50kPa, the air permeability index is 15.9, the top pressure is 9kPa, the air temperature is 750℃, and the top temperature is 24℃. At the same time, special oxygen lances are installed in the two iron ports to blow oxygen and air into the furnace, in order to heat the hearth as soon as possible (the slag and iron accumulated in the hearth are seriously insufficient and almost completely solidified).

At 1:00 on December 3, the air volume was 1000m³/min, the hot air pressure was 98kPa, the air permeability index was 12.4, the top pressure was 14kPa, the air temperature was 800°C, and the top temperature was 42°C. At this time, there was a pressure holdup phenomenon in the furnace. At 3:00, the wind pressure rose to 198kPa, and the air volume shrank to about 660m³/min, and the wind was stopped at 3:15 for processing. 3:23 Rewind, wind pressure 22kPa, air volume about 520m³/min, wind temperature 760℃, top temperature 24℃. After that, the furnace condition recovered smoothly. By 8:00, the air volume returned to 1064m³/min, the air pressure was 51kPa, the air temperature was 820℃, the top pressure was 8.7kPa, and the top temperature was 36℃. At 12:20, the air volume returned to 1460m³/min, the air pressure was 90kPa, the air temperature was 850℃, the top pressure was 18kPa, and the top temperature was 42℃.

At 7:45 on December 3, the pre-buried oxygen lance at the Nanchang iron port was automatically boiled, and the port was blocked after about 3.5t of iron was tapped; at 10:13, the oxygen lance of the north field iron port was also boiled, and the port was blocked after about 5t of iron was tapped. . At 13:15, the cumulative air consumption reached 107wm3. It is expected that the first batch of iron materials has entered the hearth, and the first furnace of iron will be organized in the south field. Due to the sufficient preparation outside the furnace, the safe tapping is about 20t. Furnace temperature [Si] 2.86%, [S] 0.060%, [Mn] 1.50%, molten iron physical heat 1274 ℃. Due to the smooth opening of the taphole of the first furnace, the fluidity of the slag and iron is relatively good. After 15.5 hours of air supply, the 14# tuyere was opened at 13:42. By 14:20, the air volume is 1529 m³/min, the wind pressure is 92kPa, the wind temperature is 920℃, the top pressure is 18.6kPa, the top temperature is 67℃, the south foot is 3.84m, and the north foot is 3.83m. At the same time, the ore batch is expanded from 15t to 16t, and the material system: C322302282222↓O305285↓ becomes C342322302222↓O325295↓, and the cutting is based on the 4.0m material line. At 14:44, the Beichang taphole was opened, about 10t of iron was tapped, the furnace temperature was [Si] 5.28%, [S] 0.022%, [Mn] 2.34%, and the physical heat of molten iron was not measured. After that, with the increase of the number of air openings, the air volume gradually increased, and the material line gradually returned to 2.0m.

During this period, the furnace top gas test was qualified at 11:30. However, due to the slow rise of the top temperature, the gas was turned off until the top temperature reached 70°C at 15:00, and the 4# tuyere was opened at 15:50, and the 5# tuyere was opened at 23:25; 7 was opened at 21:20. #風口; 17# tuyere opened at 21:30. Until 24:00 on December 3, there were 17 air outlets supplying air, the air volume reached 1800m3/min, the air pressure was 120kPa, the air temperature was 830℃, the top pressure was 55kPa, and the top temperature was 260℃.

From 00:00 on December 4th, the angle of the north field iron mouth and the south field iron mouth was adjusted from 10° to 12°. However, after adjusting the angle of the iron mouth, first the iron mouth in the north field was difficult to open, and it continued to burn until 9:00, and the opening was made with explosives; then the iron mouth in the south field also appeared difficult to open, and it exploded at 11:30. . Considering that the semi-molten slag and iron could not be completely dissolved due to insufficient heat in the hearth, the angle of the tapholes in the south and north fields was adjusted again from 12° to 6° to ensure the smooth discharge of the slag and iron. At the same time, the recovery process in the furnace is also accelerated. The 15#, 16#, and 6# tuyere openings are opened at 5:15, 13:56, and 17:10, which means that within 43 hours of air supply and ignition, 20 tuyere air supply can be achieved. condition.

On December 5, with the recovery of the hearth temperature and the improvement of the fluidity of the slag and iron, the angle of the two tapholes was gradually restored from 6° to 10°. At the same time, the recovery rhythm in the furnace also accelerated. By 2:00 on December 5th, coal injection was started, and the oxygen enrichment was 30m3/min at 8:50, and the coke load reached 3.36. By 11:40, the air volume returned to 2410m³/min, the air pressure was 230kPa, the top pressure was 144kPa, the top temperature was about 210℃, the air temperature was about 1010℃, the ore batch was 25t, the load was 3.55, and the furnace temperature was controlled at [Si] 2.0~2.5%. The material system is restored to C362342322302222↓O363343322302↓. At 7:30 on December 6th, the material system was restored to C372352332312222↓O373353332312↓, the material line was restored to 1.5m, the furnace temperature was controlled at 0.8-1.2%, and TRT was put into use at 13:30.

5 Conclusion

(1) Three days before the shutdown of the furnace, the load is removed, and the charging system with the appropriate development of the edge airflow is adopted, and manganese ore is added to wash the furnace, which provides a strong guarantee for the safe and smooth shutdown of the empty charging line. However, before and in the middle of the empty material line, due to the large use of air volume and the excessive control of the amount of water drawn, the temperature of the furnace top fluctuates greatly, and two large knocks occur, which is worth learning. In the future, in the early stage of the empty material line, the amount of water drawn must be controlled in combination with the furnace top temperature to ensure that the top temperature is greater than 250 °C.

(2) The practice of this empty material line shows that the reduction of coke load by 40.4% is too much, that is to say, when the coke load is reduced to 2.30, the furnace temperature is slightly higher and should be reduced to 2.50.

(3) During the gunning process, it is necessary to control the amount of feed and the ratio of water to be added to avoid large dry dust and more rebound materials during the process. Although it is secondary recycling and the return rate is within 5% of the control target value, the gun blocking phenomenon often occurs in the process, which affects the gunning speed.

(4) For the blast furnace under medium repair, the initial air addition and opening of the tuyere should not be too hasty, otherwise, it is easy to cause the blast furnace to be difficult to operate. At the same time, due to the poor liquid permeability of the hearth, the angle of the iron mouth should be adjusted to be as small as possible to facilitate the rapid discharge of the "cold" slag and iron accumulated in the hearth. occur.

(5) Due to the sufficient preparations, the empty material line process was successfully realized in only 11 hours, and the furnace conditions went straight after the air was supplied and ignited at 22:30 on December 2. The full tuyere operation was resumed in 43 hours, and coal injection was resumed in 51h30min. On December 10, the output reached 2569.89t (excluding the amount of slag), and the utilization coefficient reached 2.178t/m3·d. The goal of smoothly opening the furnace and reaching production quickly.