15358968703

Development characteristics of ironmaking technology in many countries in the world

2022-06-07

The blast furnace capacity in Japan is increasing, but the number of blast furnaces is decreasing. Increasing the use of non coking coal and low-quality iron ore will reduce the cost of iron making raw...

Measures for energy saving and consumption reduction in ironmaking system

2022-06-07

Abstract: with the development of society and the reduction of earth resources, higher requirements and more challenges have been put forward for various industries. However, for the blast furnace iro...

Surface Quality of Continuous Casting Billets

2022-03-24

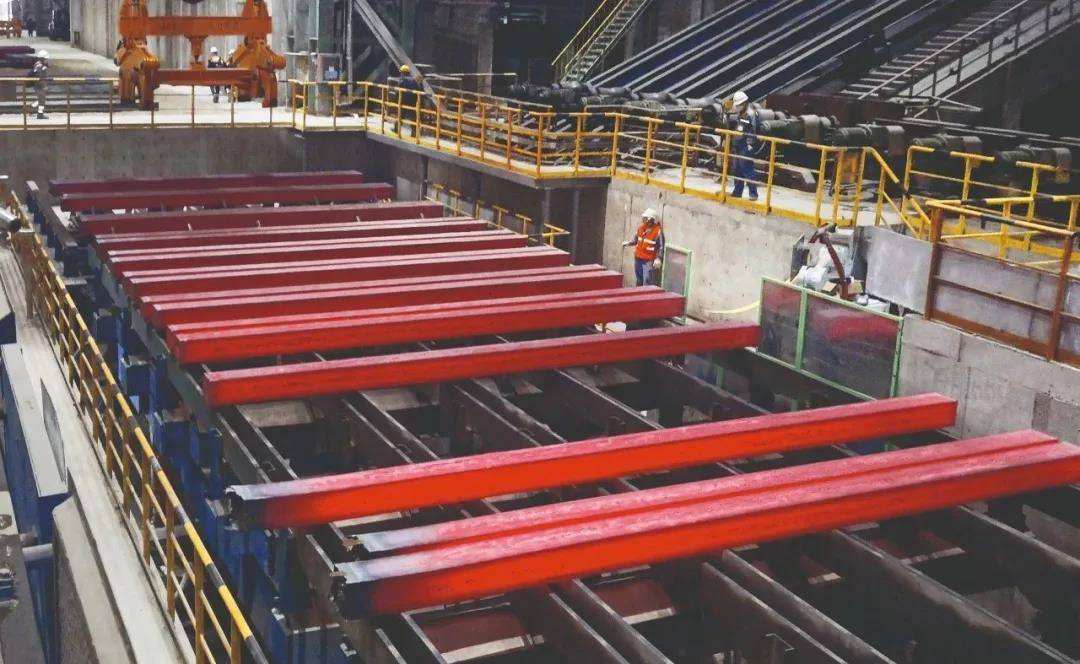

1. Surface cracks 1) Surface longitudinal cracks Longitudinal cracks on the surface of continuous casting slabs will affect the quality of rolled products. For example, a longitudinal crack with a length of 300 mm and a dep...

What are the reasons for the looseness and shrinkage of the continuous casting billet

2022-03-24

1 Introduction A steelmaking plant of an iron and steel (group) company has built a new 1800mm slab continuous casting machine. The designed slab specifications are 200mm, 220mm, 250mm thick and 1400mm~1800mm wide. During the...

Causes and control measures of four major surface defects of billet

2022-03-24

Surface defects of billets 1 Reconnect 1.1 Causes of formation a. The pouring is interrupted due to various operating failures, and reconnection defects are likely to be caused on the surface of the slab after restarting ...

Summary of control methods for large depression defects in slabs

2022-03-24

In the production of continuous casting, billet dents occur from time to time, which not only affects the qualification rate of the billet, but also causes production accidents in serious cases. There are two main types of slab...